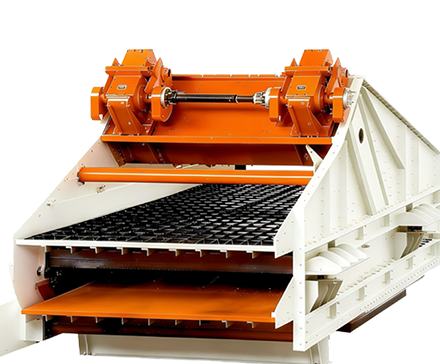

Laminated manganese steel anti-blocking screen highlights six properties and advantages

The lamination treatment of mine manganese steel anti-blocking screen is a

material surface modification technology. It improves the performance of

manganese steel screen itself by adding a layer of special polymer polyurethane

material on the surface of manganese steel screen. For manganese steel

anti-clogging screens, the lamination treatment can significantly improve the

wear resistance, impact resistance and corrosion resistance of the anti-clogging

screens, and its performance and advantages can be further improved to

effectively extend the service life of the screen.

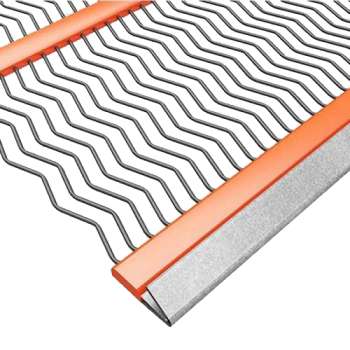

1. Significant improvement in wear resistance

A uniform rubber layer will be formed on the surface of the manganese steel

anti-blocking screen after lamination treatment. This special structure not only

increases the sealing performance of the screen, but also greatly improves its

wear resistance. In the continuous material screening process, this improvement

means that the service life of the manganese steel anti-blocking screen has been

significantly extended, thus reducing maintenance costs and downtime.

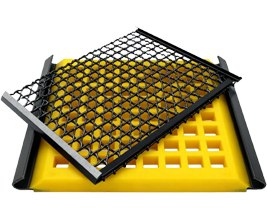

2. Optimization of anti-blocking effect

The manganese steel screen after lamination treatment has excellent

anti-blocking performance. The special material and structural design of the

laminated layer make it difficult for fine particles to adhere to the screen

holes. The rubber layer on the laminated screen can effectively reduce the

direct friction between the contact area between the material and the screen,

even during long-term continuous operation. It can also maintain high screening

efficiency under normal circumstances and effectively avoid shutdown maintenance

problems caused by hole blockage. This is especially important for sticky or wet

materials. In this way, the anti-blocking effect of the screen is optimized,

ensuring the continuity and efficiency of the screening process.

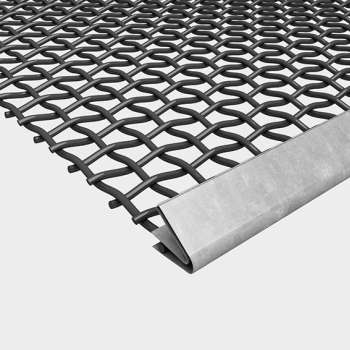

3. Enhancement of corrosion resistance

Manganese steel itself has a certain degree of corrosion resistance, and the

lamination treatment further enhances this characteristic. The laminated layer

not only increases the wear resistance of the manganese steel screen, but also

enhances its corrosion resistance. The rubber layer has a blocking effect on

corrosive substances. In humid or corrosive environments, the laminated layer

can effectively resist the erosion of the screen base material by chemicals such

as acids and alkalis, protecting the screen structure from damage, making

Screens are able to work in harsher environments, such as the chemical industry

when handling acidic or alkaline materials.

4. Reduce noise levels

In the traditional screening process, the vibrating screen will produce a

certain amount of noise. The rubber-laminated manganese steel anti-blocking

screen can reduce the noise level during work to a certain extent due to the

sound-absorbing properties of rubber, creating a relatively quiet working

environment for workers.

5. Improved screening accuracy

Due to the rubber layer on the surface of the rubber-laminated manganese

steel anti-blocking screen, the screen holes are not easily blocked by

materials, thus maintaining a high screening accuracy. Even small differences

can be effectively controlled. This precision is crucial for demanding screening

operations, ensuring consistent quality of the final product and meeting

high-standard production needs. This is an important advantage for industries

that require high-precision screening.

6. Improvement of economic benefits

Due to the existence of the laminated layer, the wear rate of the manganese

steel screen during use is greatly reduced, thereby reducing the frequency of

replacement. This directly reduces production and maintenance costs, brings

economic benefits to users, and also improves the operational stability of the

production line. In the long run, it will bring greater economic benefits to the

enterprise. Reduced replacement frequency and downtime means that the overall

operating costs of the production line will be significantly reduced.

The manganese steel anti-blocking screen after lamination treatment has

become the preferred screening solution for many industries due to its excellent

wear resistance, corrosion resistance, anti-blocking effect, low maintenance

cost, high screening accuracy and wide applicability. plan. The combination of

these properties and advantages enables this type of screen to provide more

reliable and efficient service when faced with challenging screening tasks.

Whether from the perspective of production efficiency or long-term cost savings,

the manganese steel anti-blocking screen after lamination treatment has

demonstrated its irreplaceable value and made an important contribution to the

development of modern industry.

Leave A Reply

By using form u agree with the message sorage, you can contact us directly now