-

-

-

No.1 Redstar Road, Qianpu Development Zone, Hebei China

About Us

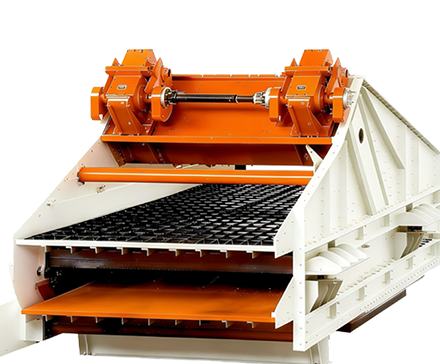

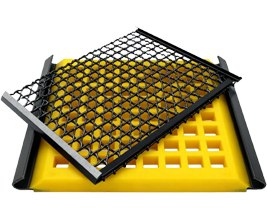

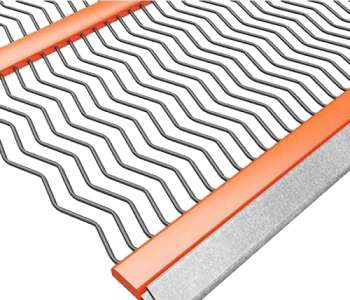

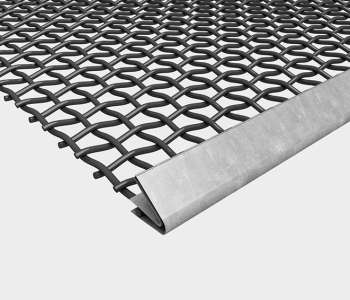

We produce high quality products with the best materials! or over 36 years, Red Star has been a company dedicated to the engineering and manufacturing of screening media that are widely used in the mining and aggregates industry.

Get a free quote

Contact Info

- No.1 Redstar Road, Qianpu Development Zone, Hebei China

- (+86) 13673237939

- hanfeng@redstarfactory.com