Industrial Applications

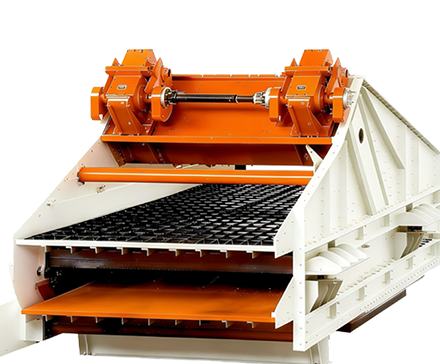

As the core sorting equipment in the industrial field, mining screens are used throughout the entire process from raw material processing, production and processing to waste recycling Through precise screening , efficiency improvement and resource optimization , they have become an indispensable "technological link " in the modern industrial system

1. Raw material pretreatment and grading

(1) Metal smelting:

In the metallurgical industries such as iron ore and copper ore, ore screens are used to classify the particle size of crushed ore (such as 0-10mm charging material and 10-30mm return material) to ensure the air permeability and smelting efficiency of blast furnaces or electric furnaces.

effect:

Improve metal recovery rate (e.g. iron ore grade increased by 5%-8% after screening);

Reduce coke consumption (uniform particle size reduces "bridging" phenomenon in the furnace).

(2) Chemical raw material processing:

Screening of catalyst carriers (such as alumina balls), plastic particles, and fertilizer raw materials to control particle size distribution (such as urea particles 1-4mm) to ensure uniformity of chemical reactions.

effect:

Avoid pipe blockage caused by agglomeration;

Improve catalyst activity (such as molecular sieve particle size error ≤ 0.05mm).

2. Precision production in manufacturing

(1) Powder metallurgy:

Screening of metal powders (such as titanium powder and tungsten powder) to a specific particle size (such as below 200 mesh) for precision manufacturing such as 3D printing and MIM (metal injection molding).

effect:

Ensure consistency of product density and mechanical properties;

Reduce sintering deformation (coarse particle ratio ≤ 0.1%).

(2) Electronic materials:

Sorting silicon micropowder (raw materials for photovoltaic cells), ceramic dielectrics (MLCC capacitors), etc., with precision reaching nanometer level (such as 325 mesh sieve filtering 5μm particles).

effect:

Improve the yield rate of electronic components (e.g., the defect rate of MLCC capacitors is reduced by 30% after screening);

Meet the ultra-high purity requirements of semiconductor materials (impurity content ≤ 1ppm).

3. Environmental protection and resource recycling

(1) Industrial solid waste treatment:

Sorting industrial wastes such as fly ash, steel slag, and red mud to extract recyclable components (such as iron particles in steel slag and floating beads in fly ash).

effect:

The resource utilization rate increased to over 60%;

Reduce landfill costs (reduced by US$50-100 per ton of solid waste disposal fees).

(2) Wastewater treatment:

Use stainless steel mesh (pore size 0.1-1mm) to intercept suspended solids in industrial wastewater (such as textile printing and dyeing fibers, electroplating sludge).

effect:

Protective membrane treatment system, extending the life of reverse osmosis membrane by 2-3 times;

Comply with industrial wastewater discharge standards (such as SS≤30mg/L).

4. Food and pharmaceutical industries

(1) Food processing:

Sifting flour, powdered sugar, milk powder, etc. to remove lumps or foreign matter (such as metal shavings) in compliance with HACCP food safety standards.

effect:

Ensure product fineness (such as flour passing through a 100-mesh sieve);

Prevent consumer complaints and recall risks caused by foreign matter.

(2) Pharmaceutical industry:

Use 316L stainless steel vibrating screen to grade drug powders and granules (e.g. 20-60 mesh) to meet GMP clean room requirements.

effect:

Controlling drug dissolution rate (particle size affects bioavailability);

Avoid cross contamination (fully enclosed screening design).

How do I choose the right type of screen mesh for my material?

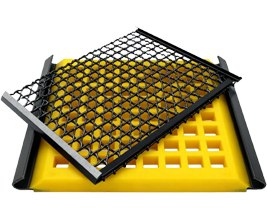

Selection depends on material hardness, moisture content, particle size, and impact force:

-

Wet or sticky materials → Polyurethane mesh (anti-clogging)

-

High abrasion materials → Manganese steel woven mesh or perforated plate

-

High-precision screening → Stainless steel woven mesh

-

Heavy impact materials → Steel-edge PU panels or rubber screen panels

Choosing the correct mesh improves output and reduces downtime.

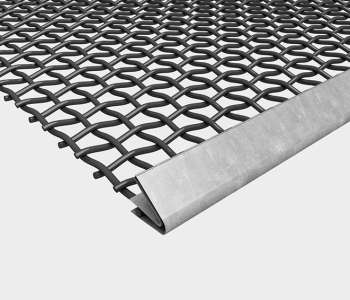

What is the typical service life of mining screen mesh?

Service life varies with material abrasiveness, vibration frequency, installation tension, and screen type:

-

Polyurethane mesh: 3–12 months

-

Manganese steel mesh: 1–6 months

-

Stainless steel mesh: 2–8 months

-

Rubber panels: 4–12 months

Proper tensioning and selecting the right aperture significantly extend lifespan.

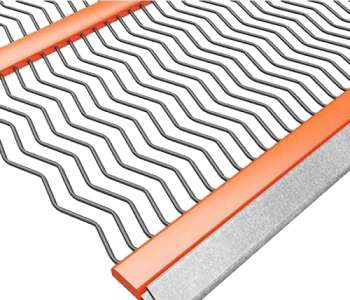

Why does my screen mesh clog, and how can I prevent it?

Clogging occurs due to moisture, irregular particle shapes, or unsuitable aperture designs.

Prevention methods:

-

Use self-cleaning screens (wave or harp type)

-

Switch to polyurethane anti-blinding mesh

-

Adjust vibration amplitude and screen angle

-

Pre-screen wet or muddy materials

Anti-clogging solutions greatly improve screening efficiency.

What should I pay attention to when replacing the screen mesh?

Key points during replacement include:

-

Ensuring consistent tension across the entire screen

-

Checking the screen frame for deformation

-

Matching hook types or fastening systems with your screen machine

-

Cleaning the deck to remove remaining material

Proper installation reduces breakage and improves screening accuracy.

How can I improve the overall screening efficiency?

Screening efficiency can be improved by:

-

Choosing the right aperture and mesh material

-

Adjusting vibration frequency and screen inclination

-

Maintaining uniform material feeding

-

Using multi-stage screening designs

-

Performing regular maintenance on screen decks and meshes

Efficiency improvements of 10–30% are commonly achievable.