Double-wire woven wire screen is ideal for heavy impact applications on top screen decks thanks to its high tensile strength and ductility. This woven wire screen can withstand up to 4 times more impact force than heavier single-strand woven screen. With higher opening area than perforated plate screen, double-wire woven screen can deliver more material throughput by up to 50%.

Double-wire woven wire screen is ideal for heavy impact applications on top screen decks thanks to its high tensile strength and ductility. This woven wire screen can withstand up to 4 times more impact force than heavier single-strand woven screen. With higher opening area than perforated plate screen, double-wire woven screen can deliver more material throughput by up to 50%.

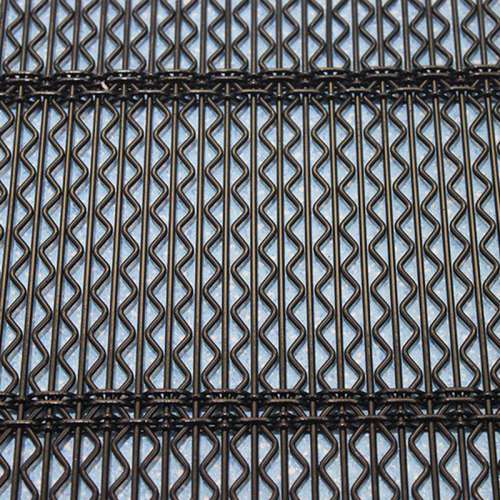

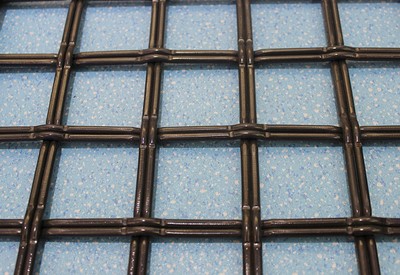

A double-wire woven wire screen is a specialized type of woven mesh screen that uses two parallel wires instead of a single wire for each strand in the weave. This design enhances the screen's strength and durability, making it suitable for heavy-duty applications, especially in industries where abrasion, impact, or heavy loads are common.

Key Features:

Double-Wire Construction: Two wires are woven together in parallel for both the warp (vertical) and weft (horizontal) directions, creating a stronger and more durable mesh structure.

Increased Strength: The double-wire design significantly improves the screen’s resistance to wear, stretching, and breakage, especially under heavy loads.

Customizable Mesh Size: Like other woven wire screens, the opening size can be customized depending on the application’s needs, offering flexibility in particle separation or filtration.

Benefits:

Extended Lifespan: Double-wire screens last longer compared to single-wire screens, especially in abrasive environments like mining or aggregate processing.

Reduced Downtime: The robust design means fewer screen replacements or repairs, minimizing operational interruptions.

Better Impact Resistance: Ideal for high-impact applications where materials hit the screen with considerable force, reducing the risk of breakage or deformation.

Specifications

Materials available

patented wire (65mn manganese steel wire), stainless steel, medium carbon steel, high carbon steel

Opening size

25.4-200mm

Wire

3.05-19.05mm

Screen size

Max. 3m width