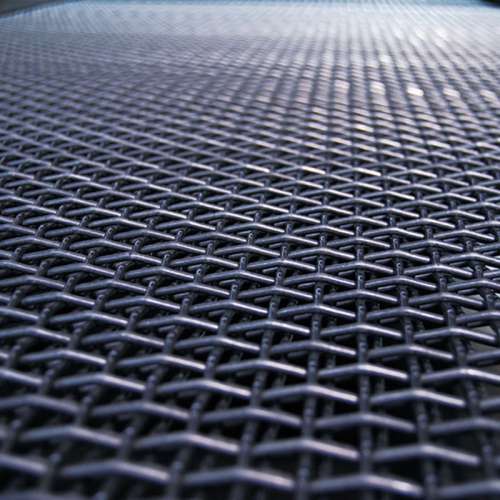

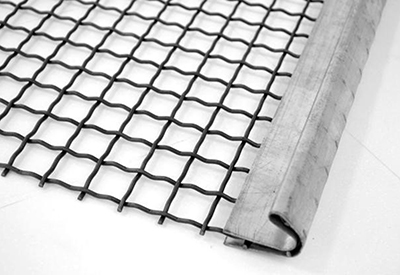

Square opening wire mesh is a most commonly used screening media by reason of its highly precise mesh apertures. Red Star’s woven wire screen is offered with the most precision mesh aperture within the global industry. Our square wire mesh features an aperture deviation of only ±3%, which is far superior to international standards of DIN47833 (Europe) and ASTM 2016-15 (North America).

We are able to deliver options of woven wire weave styles to perfectly suit your filtration and separation applications, such as plain weave (double crimp), lock crimp weave, flat top weave and intercrimp weave.

Specifications

Materials available

patented wire (65mn manganese steel wire), stainless steel, medium carbon steel, high carbon steel

Opening size

1.25-200mm

Wire

0.8-19.05mm

Screen size

Max.3m width

Weave Styles

Plain Weave/ Double Crimp Woven Wire

The advantages of plain weave woven wire mesh are simplicity and high weave precision. This type of weave is used where the opening is relatively small, can guarantee achieving high efficiency and sustained performance screening.

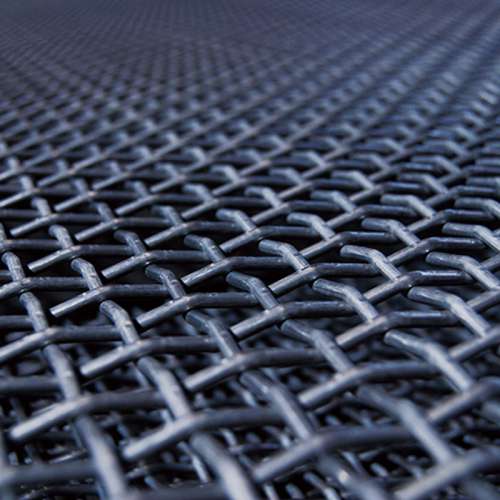

Lock Crimp Woven Wire

In the lock crimp weave type, weft and warp wires pass each other and get locked together at the point of intersection. The crimping is done to lock the wires to prevent from abrasion caused by wire movements. This weave type works perfectly for screening applications where the aperture size and wire diameter are relatively large.

Flat Top Woven Wire

The flat top weave offers a smooth surface for easier material flow. This type of woven wire provides long abrasion resistance lifetime since there are no obstacles on the smooth surface side to strike the material during its flowing.

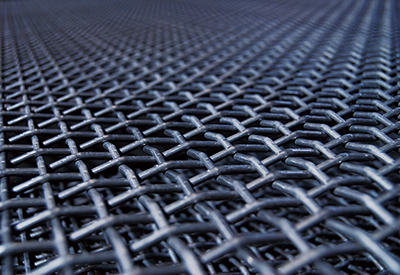

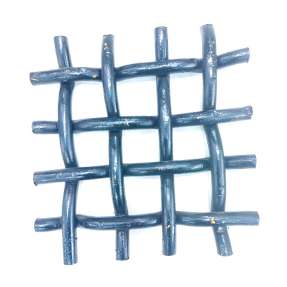

Intercrimp Woven Wire

Intermediate crimp, or simply intercrimp has extra crimps in warp and weft wires between the intersections, it is primarily used where larger aperture size is required while the wire diameter remains stable. The rigidity and stability are greater than common woven wire screen.

Thanks to its feature of large open area, the intercrimp woven wire screen is ideally suited for use in applications with high throughput.

Aplicaciones

Las mallas metálicas cuadradas se utilizan principalmente como cribas en diversas industrias, como minería, canteras, placas de cribado, cribas trituradoras, cribas de tambor, cribas vibratorias y cribas utilizadas en equipos de construcción de carreteras o equipos de mezcla de asfalto. Y muchas más industrias, incluidas química, farmacéutica, seguridad y protección, construcción, etc.