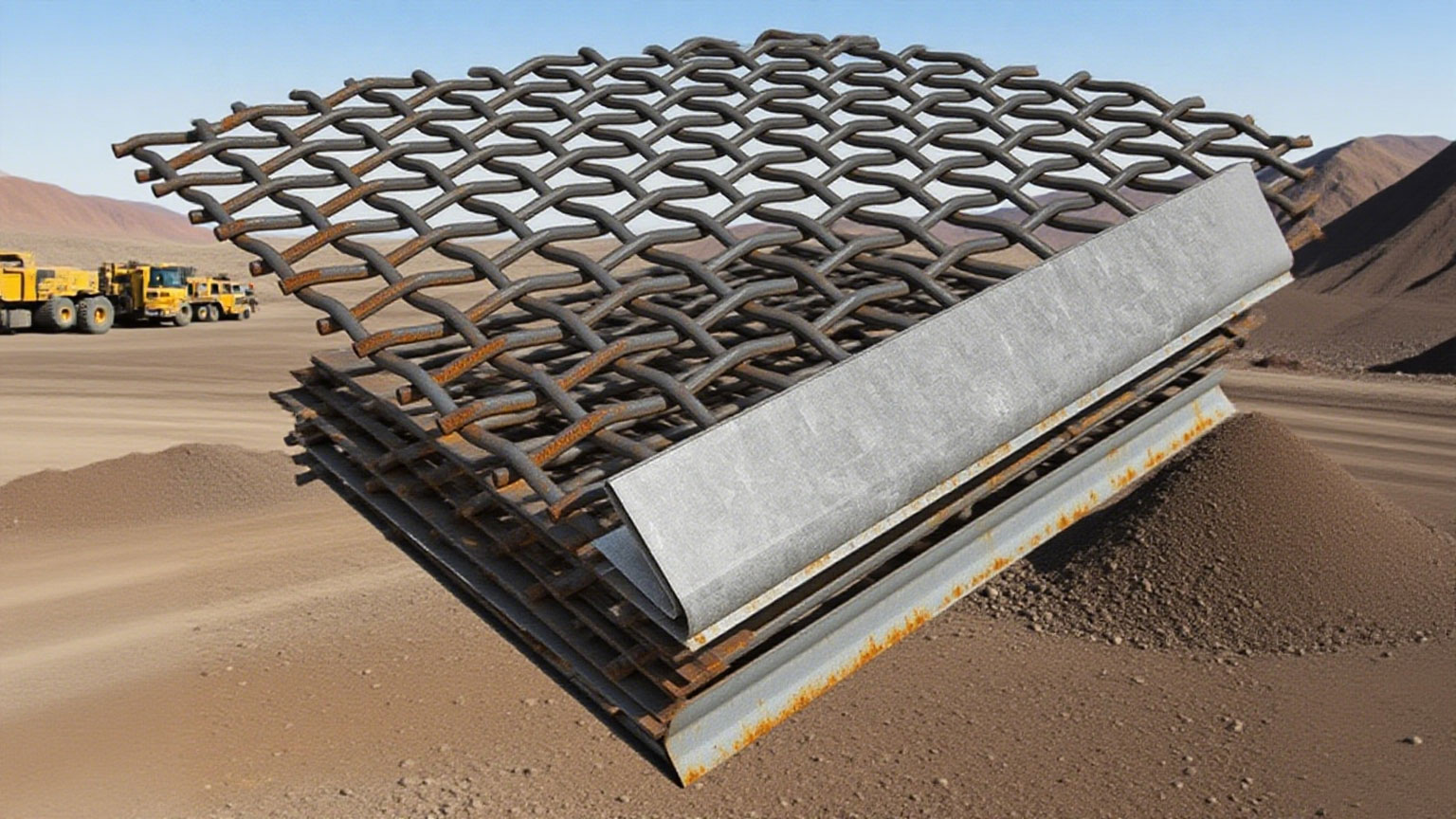

FerroMax®

Strong and durable

FerroMax®: Designed for extreme mining environments to reduce frequent changes and costly downtime.

FerroMax®: Designed for extreme mining environments to reduce frequent changes and costly downtime.

Low-carbon steel screens fail rapidly in mining environments, creating operational and financial burdens.

65Mn low-carbon steel screens develop red rust within 48–72 hours, creating a cascade of operational issues and financial losses for mining operations.

"We were forced to shut down the machine twice a month to replace the screens. The labor cost for screen replacement alone was ≥$2,800/month."

The true cost of 65Mn steel corrosion extends far beyond replacement parts.

For 65Mn steel of the same specification in an environment with 40°C, 75% RH, and Cl⁻-containing dust:

If the mesh aperture is enlarged by 20%, the screening efficiency will suddenly drop by 30%.

Corrosion pits combined with vibration reduce fatigue limits by 60%, leading to a 15% annual risk of sudden fracture.

Each downtime loss is ≥$7,000, with an annual hidden cost exceeding $140,000.

Engineered for Extreme Mining Environments to Eliminate Corrosion Issues

FerroMax® screens outperform conventional 65Mn steel in all critical performance metrics, delivering exceptional durability in harsh mining environments.

| PERFORMANCE METRIC | 65Mn STEEL | FERROMAX® SERIES |

|---|---|---|

| Indoor storage anti-rust period | 10–15 days | ≥ 365 days |

| Actual anti-rust period in mines | 5–10 days | 3–6 months |

| Annual corrosion rate | 0.39–0.65 mm | ≤ 0.05 mm |

| Fatigue life | 1.2×10⁶ cycles | ≥ 4.5×10⁶ cycles |

| Annual replacement frequency | 12–24 times | 4–6 times |

"Since implementing FerroMax® screens, our downtime has decreased by 75%, saving us over $200,000 annually."

— Project Manager, Qianpu Developing Zone Anping, Hebei Pro.

Our proprietary technology combines advanced materials science with innovative engineering.

① 30-40μm UV-resistant hard film, QUV aging ≥500h

② Rainwater erosion resistance (film thickness loss ≤10% after 1h of erosion)

③ Solvent-free, VOC=0, ROHS certified

65Mn, quenched & twice isothermal-drawn, achieving a tensile strength of 1600–1800 MPa. The coating forms a metallurgical bond with the substrate, resisting impact and preventing peeling.

Patented "double-lock" weaving nodes reduce the stress concentration factor from 3.0 to 1.4, lowering the probability of fatigue crack initiation by 60%.

FerroMax® has passed rigorous 1000-hour salt spray testing, confirming its superior corrosion resistance. The unique combination of materials and manufacturing processes delivers 275% longer fatigue life compared to #55 steel.

"FerroMax® screens demonstrated exceptional performance in our accelerated corrosion testing, outperforming all conventional alternatives."

Saving $25,000 per year per screening machine

The economic benefits of FerroMax® extend beyond reduced replacement frequency, impacting multiple cost centers in your operation.

PRODUCTION LINE SAVINGS

An entire production line with 8 machines can save approximately $200,000 annually

(Data from a cobblestone quarry project in China)

| ITEM | MONTHLY REPLACEMENT | BI-MONTHLY REPLACEMENT | ANNUAL SAVINGS |

|---|---|---|---|

| Screen usage | 12 pieces | 6 pieces | 72 pieces |

| Price per piece | $110–$170 | $110–$170 | — |

| Screen procurement cost | $1,320–$2,040 | $660–$1,020 | $660–$1,020 |

| Replacement labor cost | 12 × $550 = $6,600 | 6 × $550 = $3,300 | $3,300 |

| Shutdown loss | 12 × $3,500 = $42,000 | 6 × $3,500 = $21,000 | $21,000 |

| TOTAL ANNUAL SAVINGS | — | — | $24,960–$25,320 |

Average ROI period: 1.2 months

CHOOSE FERROMAX® = CHOOSE HIGHER EFFICIENCY AND LOWER COSTS

Experience the FerroMax® difference with our no-risk trial program

A 1m×2m FerroMax®-AR40 (40mm square holes, 8mm wire diameter) will be delivered this week for on-site testing.

Our engineers can bring handheld corrosion thickness gauges to record rust differences at 7, 30, and 90 days.

If the trial is successful, an annual framework agreement can be signed, with 5% safety stock reserved to ensure delivery within 48 hours.

| Square Aperture (mm) |

Light Duty | Medium Duty | Heavy Duty | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Wire Dia (mm) |

kg/m² | OA% | Wire Dia (mm) |

kg/m² | OA% | Wire Dia (mm) |

kg/m² | OA% | |

| 2.00 | - | - | - | - | - | - | 1.37 | 7.1 | 35 |

| 3.15 | - | - | - | 2.00 | 9.9 | 37 | 2.50 | 14.1 | 31 |

| 4.0 | 2.00 | 8.50 | 44 | 2.50 | 12.2 | 38 | 3.05 | 16.8 | 32 |

| 5.0 | 2.00 | 7.80 | 51 | 2.50 | 16.6 | 44 | 3.05 | 14.7 | 38 |

| 6.0 | 9.00 | 21.00 | 67 | 10.00 | 25.4 | 64 | 11.20 | 31.1 | 61 |

| 8.0 | 9.00 | 19.50 | 69 | 10.00 | 23.4 | 67 | 11.20 | 28.4 | 64 |

| 10 | 10.00 | 23.20 | 69 | 11.20 | 26.0 | 67 | 12.50 | 31.8 | 64 |

| 12 | 10.00 | 10.00 | 82 | 11.20 | 14.3 | 81 | 12.70 | 17.6 | 79 |

* The table shows some common sizes. A complete specification table is available upon request. The 40mm size (highlighted) is the most commonly used mining screen size.

Take the first step toward eliminating corrosion-related issues and saving thousands annually. Request your free FerroMax® sample today.

REQUEST FREE SAMPLE