Advantages of

Red Star-Polyurethane Fine Mesh

Polyurethane Fine Mesh

Impact Resistance: Prevents wear on the underlying layer. units.

High Tensile Strength and Vibration Frequency: The fine mesh has high tensile strength and high vibration frequency. Screening efficiency is increased by 10%, and the permeability rate is 11% higher.

Single Installation, No Need for Repeated Tensioning: Once installed, there is no need to retighten repeatedly.

Long Service Life:The maximum service life can reach up to 9,000 hours.

Environmentally Friendly and Recyclable: The material is environmentally friendly and recyclable.

Injection Molding Process: High precision of sieve holes and high opening rate; no notches and no burrs in the holes.

Differentiation of

Red Star-Polyurethane Fine Mesh

1. Different structures:

Our polyurethane fine screen mesh is different from others. We will add an elastic cloth to the bottom of the screen mesh.

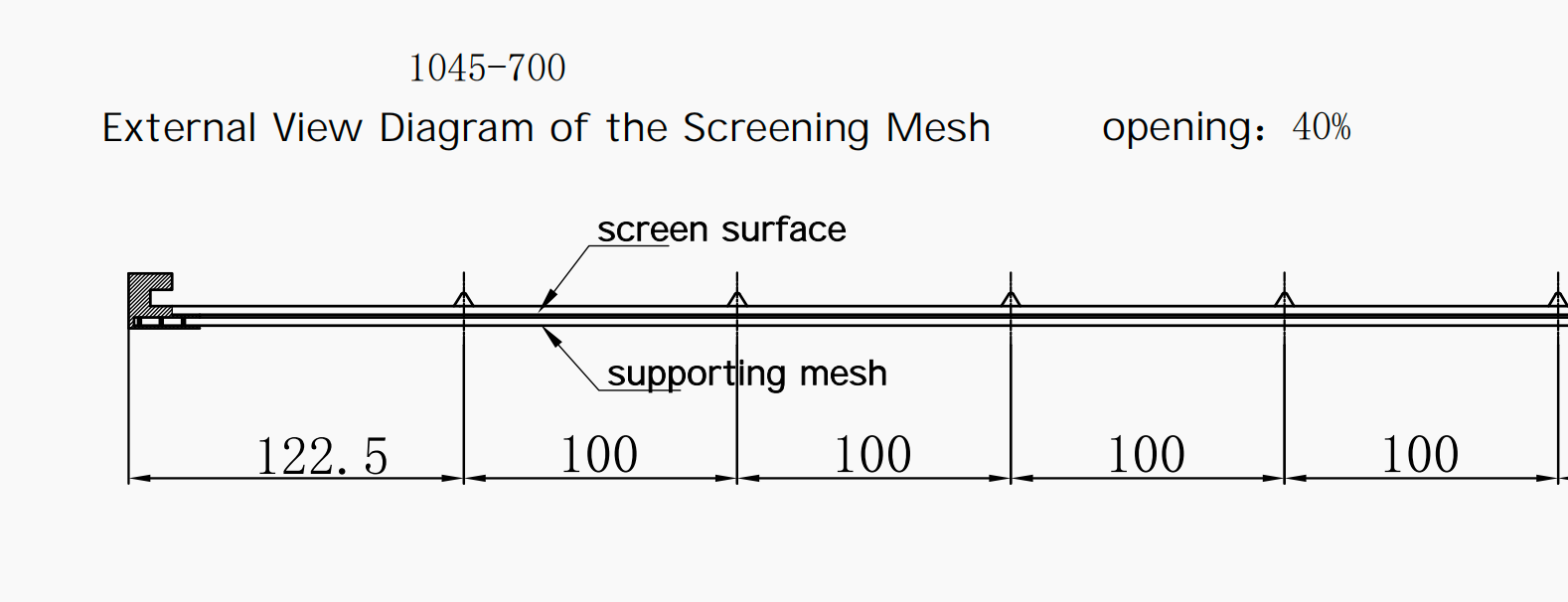

Elastic Cloth (as shown in Figure a).

(img a. Screen surface is the mesh for screening materials; supporting mesh is Elastic Cloth )

2. The benefits brought by this structure are as follows:

a. The tensile strength of the screen mesh is increased. A higher tensile strength makes the screen mesh tighter after tensioning. With the vibration frequency of the screening machine unchanged, the vibration frequency of the high-tensile-strength screen mesh will be higher. Given the same open area ratio, our screen mesh can achieve a 10% increase in screening efficiency and an 11% increase in screening rate.

b. The increased tensile strength of the screen mesh eliminates the need for repeated tensioning. Once installed, the screen mesh can remain in place until it wears out, without the need to shut down the machine to retension the mesh. This can save a significant amount of labor costs and reduce production losses caused by downtime. But traditional screen meshes need to be shut down regularly (perhaps every 1 to 1.5 months) to retension the mesh. This is due to their low tensile strength and high elongation rate. If not retensioned periodically, the screen mesh will become loose, which can lead to material accumulation, poor screening efficiency, and faster wear of the screen mesh.

c. The Elastic Cloth protects the polyurethane fine mesh from the impact of the second layer of material. In multi-layer screening machines, where the screen bed space is limited, the polyurethane fine mesh is often damaged on the backside due to the impact of the second layer of material. To protect the polyurethane mesh, we have added an Elastic Cloth to the back of each screen mesh (as shown in Figure b).

(b.Elastic Cloth)

3.Service Life

The maximum service life can reach up to 9,000 hours.

4.Environmental Protection and Recyclability

TPU products are formed through a physical reaction and can be recycled and reused. They are mature environmentally friendly material products.

5.Injection Molding Process

Advanced precision mold manufacturing technology is used. The mesh holes have high precision, no notches, and no burrs. This ensures the stability of the mesh slot size during use, maximizes the stability of the screened particle size, prevents clogging of holes, and ensures a high opening rate, thereby maximizing screening efficiency.